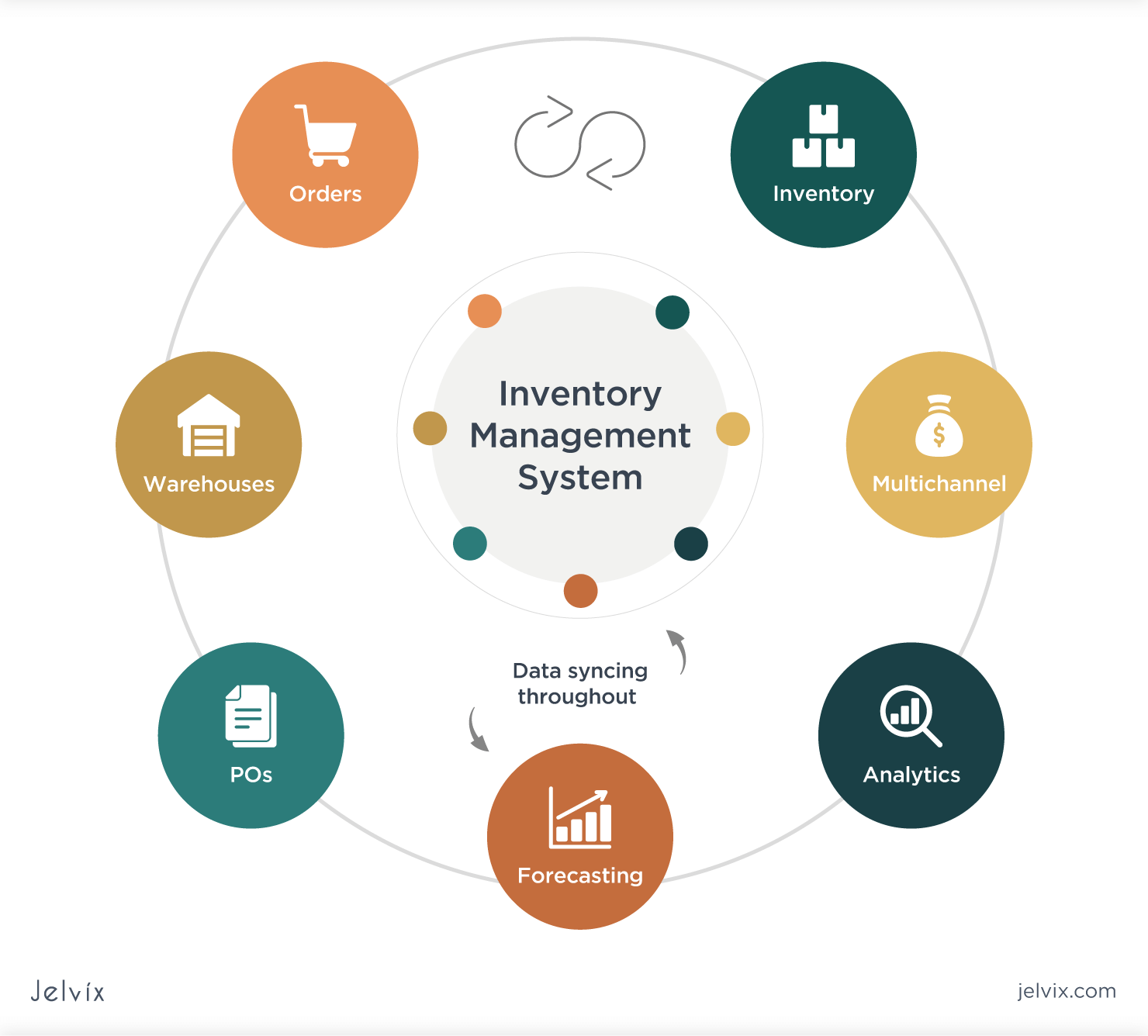

Inventory management systems small business – In the realm of small businesses, inventory management systems (IMS) play a pivotal role in driving efficiency, reducing costs, and enhancing overall operations. By implementing an effective IMS, small businesses can gain a competitive edge and unlock their full potential.

IMSs offer a multitude of benefits, including improved accuracy, reduced waste, increased efficiency, and real-time visibility into inventory levels. With the advent of cloud-based solutions, IMSs have become more accessible and affordable for small businesses of all sizes.

Inventory Management for Small Businesses

Effective inventory management is crucial for small businesses to optimize operations, reduce costs, and enhance customer satisfaction. Proper inventory management practices can help businesses track stock levels, prevent shortages, and minimize waste, leading to increased profitability and efficiency.

According to a study by the National Retail Federation, businesses that implement effective inventory management strategies can reduce inventory costs by up to 20% and increase sales by up to 15%. Another study by the American Productivity & Quality Center found that small businesses that adopted inventory management systems experienced a 25% reduction in inventory carrying costs and a 10% increase in customer satisfaction.

Benefits of Inventory Management for Small Businesses

- Reduced Costs:Effective inventory management helps businesses minimize inventory waste, prevent overstocking, and negotiate better prices with suppliers.

- Improved Efficiency:Automated inventory management systems streamline processes, reduce manual labor, and free up time for other business activities.

- Increased Sales:Accurate inventory tracking helps businesses avoid stockouts, leading to increased sales and customer satisfaction.

- Improved Customer Service:Real-time inventory visibility enables businesses to provide accurate order fulfillment estimates and respond quickly to customer inquiries.

- Enhanced Decision-Making:Inventory data provides valuable insights into product demand, sales trends, and supplier performance, aiding in informed decision-making.

Benefits of Inventory Management Systems

Inventory management systems provide numerous advantages to small businesses, streamlining operations and enhancing efficiency. These systems offer improved accuracy, reduced costs, and increased productivity, enabling businesses to make informed decisions and optimize their inventory levels.

Improved Accuracy

Inventory management systems automate inventory tracking, reducing the risk of human error and ensuring real-time visibility into stock levels. This accuracy helps businesses avoid overstocking or understocking, minimizing losses and optimizing cash flow.

Reduced Costs

By optimizing inventory levels, businesses can reduce carrying costs associated with excess inventory, such as storage, insurance, and handling. Inventory management systems also help businesses identify slow-moving or obsolete items, allowing them to adjust their purchasing strategies and minimize waste.

Increased Efficiency

Inventory management systems streamline inventory management processes, freeing up time for other tasks. Automated inventory tracking, order processing, and reporting reduce the need for manual data entry and paperwork, improving productivity and efficiency.

Types of Inventory Management Systems

Inventory management systems come in various types, each with its own set of advantages and disadvantages. Understanding these types is crucial for businesses to choose the most suitable solution for their specific needs.

Cloud-Based Systems

- Advantages:Accessibility from anywhere with an internet connection, scalability, cost-effectiveness.

- Disadvantages:Dependency on internet connectivity, security concerns.

On-Premise Systems

- Advantages:Greater control over data, higher security, customization options.

- Disadvantages:Higher upfront costs, maintenance and upgrade responsibilities, limited accessibility.

Hybrid Systems, Inventory management systems small business

- Advantages:Combines benefits of both cloud and on-premise systems, flexibility.

- Disadvantages:Can be more complex to implement and manage.

Selecting an Inventory Management System

Choosing the right inventory management system for your small business is crucial for efficient operations and accurate stock control. Here’s a step-by-step guide to help you make an informed decision:

Step 1: Assess Your Business Needs

Start by understanding your business’s specific requirements. Consider factors such as the size of your inventory, the industry you operate in, and the volume of transactions you handle.

Step 2: Research Available Systems

Explore the market for inventory management systems that cater to small businesses. Read reviews, compare features, and consult with industry experts to identify potential solutions.

Step 3: Consider Budget and Scalability

Set a realistic budget for your inventory management system. Ensure that the system you choose can scale as your business grows, accommodating future expansion.

Step 4: Evaluate Integration and Compatibility

Consider how the inventory management system will integrate with your existing business software, such as accounting and e-commerce platforms. Seamless integration ensures data accuracy and efficient workflows.

Step 5: Seek Professional Advice

If needed, consult with a business consultant or IT professional to help you select the best inventory management system for your unique needs.

Implementing an Inventory Management System

Implementing an inventory management system can streamline operations, improve accuracy, and reduce costs. The process involves several key steps to ensure a successful transition.

Data migration is crucial, requiring careful planning and execution to transfer existing inventory data into the new system. This includes mapping fields, ensuring data integrity, and verifying accuracy.

Training

Training staff on the new system is essential for its effective use. Comprehensive training should cover all aspects of the system, including navigation, data entry, and reporting. Hands-on exercises and simulations can reinforce learning and build confidence.

Ongoing Maintenance

Regular maintenance is necessary to keep the system functioning optimally. This includes software updates, data backups, and system monitoring. Regular audits and reviews can identify areas for improvement and ensure ongoing accuracy.

Best Practices for Inventory Management: Inventory Management Systems Small Business

Effective inventory management is crucial for optimizing inventory levels, reducing waste, and ensuring business efficiency. Industry best practices provide valuable guidance for small businesses to enhance their inventory management processes.

Inventory Forecasting

Inventory forecasting involves predicting future demand based on historical data, market trends, and industry analysis. Accurate forecasting helps businesses maintain optimal inventory levels, preventing overstocking and stockouts. It enables businesses to anticipate demand fluctuations and plan for production and procurement accordingly.

Cycle Counting

Cycle counting is a regular process of physically verifying inventory levels against records. It helps identify discrepancies, ensures accuracy, and prevents inventory shrinkage. By conducting cycle counts, businesses can minimize errors, optimize stock levels, and improve inventory visibility.

Safety Stock Management

Safety stock refers to the extra inventory held to buffer against unexpected demand or supply disruptions. Determining the appropriate safety stock levels is crucial to prevent stockouts while minimizing holding costs. Safety stock management involves monitoring inventory levels, analyzing demand patterns, and considering lead times to maintain optimal safety stock levels.

Case Studies

Numerous small businesses have achieved remarkable results by implementing inventory management systems. These case studies highlight the specific challenges they faced and the tangible benefits they gained.

Let’s delve into some compelling examples:

Case Study: A Growing Online Retailer

- Challenge:Rapid growth led to increased stock complexity and manual inventory tracking inefficiencies.

- Solution:Implemented an inventory management system that automated inventory tracking, order fulfillment, and reporting.

- Benefits:

- Reduced inventory holding costs by 20%.

- Improved order accuracy by 95%.

- Enhanced customer satisfaction with faster delivery times.

Emerging Trends in Inventory Management

Inventory management is constantly evolving, with new technologies and practices emerging to help businesses improve their efficiency and accuracy. Two of the most important trends in inventory management today are the use of artificial intelligence (AI) and machine learning (ML).These technologies are transforming inventory management practices by automating tasks, providing real-time data, and helping businesses make better decisions.

AI and Machine Learning in Inventory Management

AI and ML can be used to automate a variety of inventory management tasks, such as:

- Forecasting demand

- Optimizing inventory levels

- Managing stock levels

- Generating reports

By automating these tasks, businesses can save time and money, and improve their overall efficiency.AI and ML can also provide businesses with real-time data on their inventory levels. This data can be used to make better decisions about when to order more inventory, and how much to order.

By having access to real-time data, businesses can avoid overstocking or understocking, and ensure that they always have the right amount of inventory on hand.Finally, AI and ML can help businesses make better decisions about their inventory management practices. By analyzing data on past sales, demand patterns, and other factors, AI and ML can help businesses identify areas where they can improve their efficiency and accuracy.

Conclusion

In conclusion, inventory management systems are essential tools for small businesses seeking to streamline operations, optimize inventory levels, and drive profitability. By carefully selecting and implementing an IMS that aligns with their specific needs, small businesses can unlock a wealth of benefits and position themselves for success in today’s competitive marketplace.

Expert Answers

What are the key benefits of using an IMS for small businesses?

Improved accuracy, reduced waste, increased efficiency, real-time visibility into inventory levels, and enhanced customer satisfaction.

What are the different types of IMSs available?

Cloud-based, on-premise, and hybrid solutions.

How do I choose the right IMS for my small business?

Consider factors such as business size, industry, budget, and specific inventory management needs.

What are some best practices for inventory management?

Inventory forecasting, cycle counting, safety stock management, and regular inventory audits.