Inventory programs for small businesses play a pivotal role in streamlining operations, reducing costs, and boosting profitability. These innovative tools empower businesses to efficiently manage their inventory, optimize stock levels, and gain valuable insights into their supply chain. As a result, small businesses can stay competitive, meet customer demands, and position themselves for long-term growth.

From real-time inventory tracking to automated reordering, inventory programs offer a range of features tailored to the unique needs of small businesses. Whether you’re just starting out or looking to scale your operations, an inventory program can help you take control of your inventory and unlock its full potential.

Inventory Management Overview: Inventory Programs For Small Businesses

Inventory management is the process of tracking and managing the stock of goods and materials used in a business. It involves ensuring that the right amount of inventory is available at the right time and place, while minimizing costs. Effective inventory management is crucial for small businesses as it helps them avoid stockouts, reduce waste, and improve profitability.

Importance of Inventory Management for Small Businesses

Inventory management is important for small businesses for several reasons:

- Prevents stockouts: Stockouts occur when a business runs out of a product that customers want to buy. This can lead to lost sales, dissatisfied customers, and damage to the business’s reputation.

- Reduces waste: Excess inventory can lead to waste if products become obsolete, damaged, or expire before they can be sold. Effective inventory management helps businesses minimize waste by ensuring that they only have the inventory they need.

- Improves profitability: Effective inventory management can help businesses improve profitability by reducing costs associated with holding inventory, such as storage costs, insurance costs, and the cost of capital tied up in inventory.

Types of Inventory Programs

Inventory programs are designed to assist businesses in managing their inventory levels, ensuring they have the right products in the right quantities to meet customer demand while minimizing waste and loss.

There are several types of inventory programs available, each with its own set of features and benefits. The most common types include:

Perpetual Inventory Systems

- Provide real-time visibility into inventory levels.

- Automatically update inventory records as transactions occur.

- Enable businesses to track inventory movements and identify trends.

Periodic Inventory Systems

- Involve manually counting inventory at regular intervals.

- Provide a snapshot of inventory levels at a specific point in time.

- Suitable for businesses with low inventory turnover and stable demand.

Hybrid Inventory Systems

- Combine features of both perpetual and periodic inventory systems.

- Use perpetual inventory systems for high-value or fast-moving items and periodic inventory systems for low-value or slow-moving items.

- Provide flexibility and cost-effectiveness.

Cloud-Based Inventory Systems

- Hosted on remote servers and accessible via the internet.

- Offer scalability, flexibility, and real-time data access.

- Suitable for businesses with multiple locations or remote teams.

On-Premises Inventory Systems

- Installed and maintained on the business’s own servers.

- Provide greater control over data and security.

- Suitable for businesses with large or complex inventory requirements.

Choosing the Right Inventory Program

The choice of inventory program depends on several factors, including the size of the business, the type of inventory, the frequency of inventory transactions, and the budget. It is important to evaluate the features and benefits of each type of inventory program to determine the best fit for the specific needs of the business.

Selecting an Inventory Program

Choosing the right inventory program for your small business is essential for efficient inventory management. Consider the following factors to make an informed decision:

- Business Size:Small businesses with limited inventory needs may opt for simple programs, while larger businesses require more comprehensive solutions.

- Industry:Specific industries may have specialized inventory requirements, so consider programs tailored to your industry.

- Budget:Determine your budget for an inventory program and compare the costs of different options.

Key Features to Consider

When evaluating inventory programs, focus on features that align with your business needs, such as:

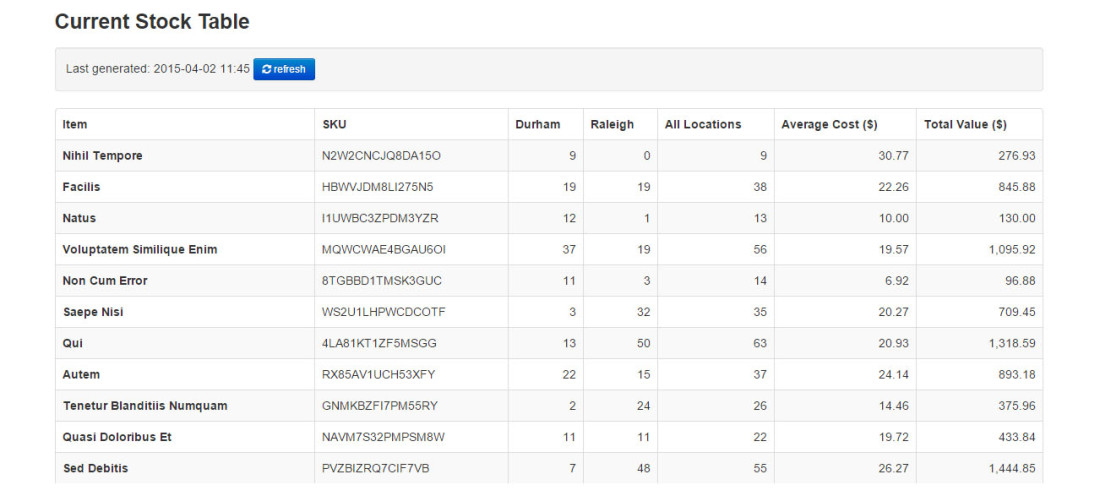

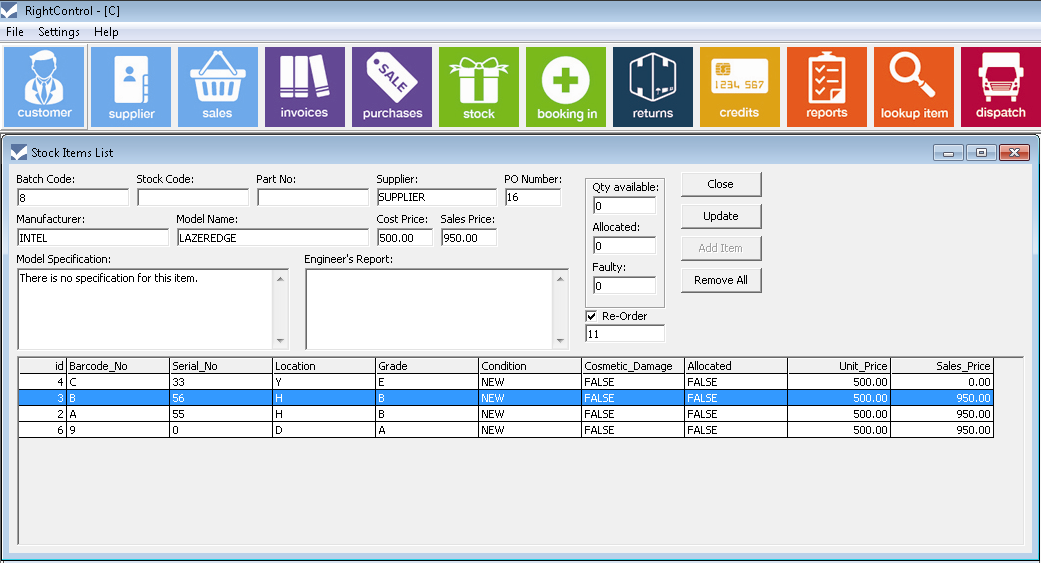

- Inventory Tracking:Track inventory levels, locations, and movement.

- Purchase Order Management:Create and manage purchase orders.

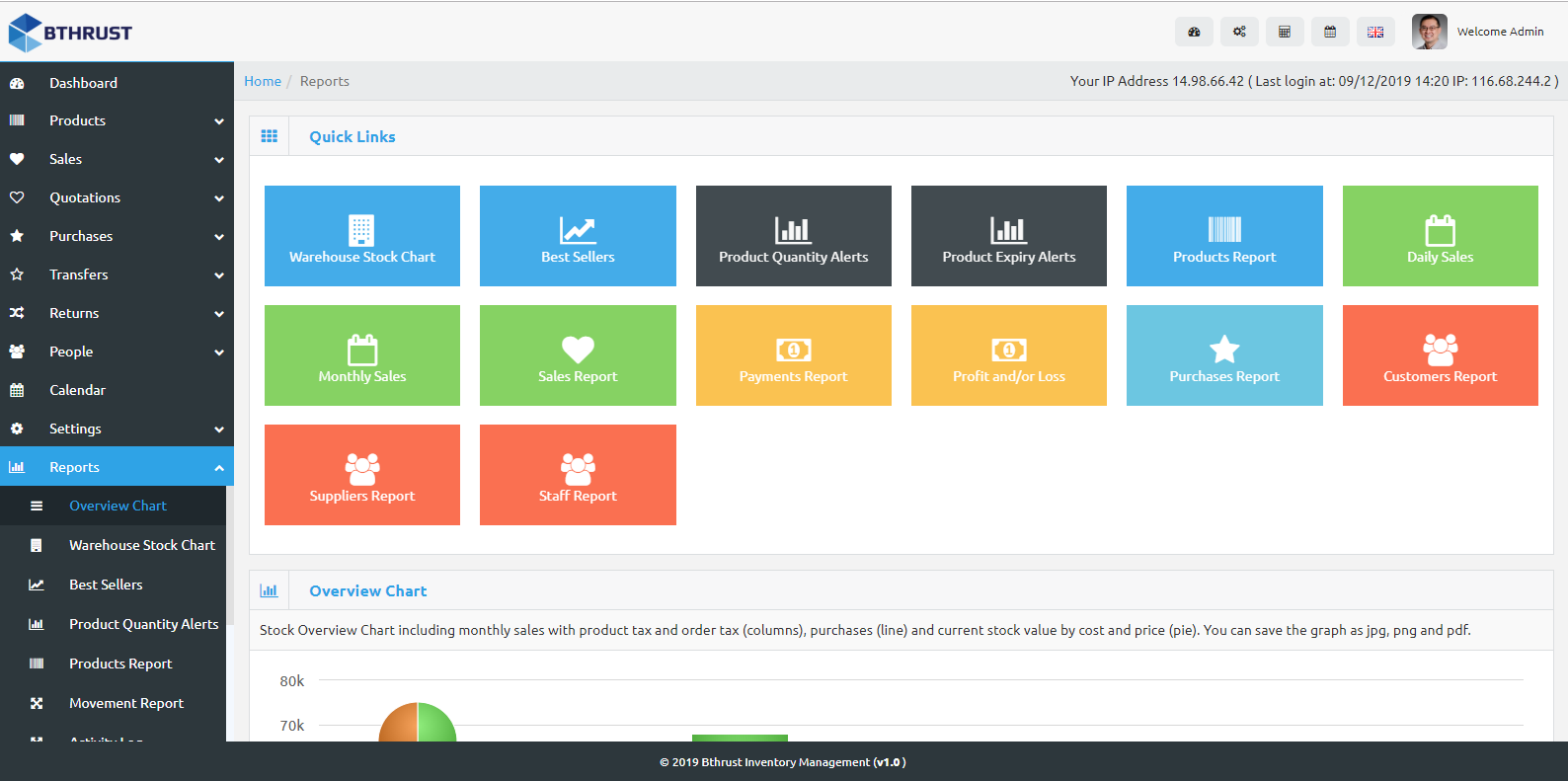

- Reporting and Analytics:Generate reports on inventory performance and trends.

- Integration:Seamlessly integrate with other business systems, such as accounting or POS.

- Mobile Access:Manage inventory on the go with mobile apps.

Benefits of Using an Inventory Program

Utilizing an inventory program offers a multitude of advantages for small businesses, enabling them to streamline operations, reduce costs, and enhance profitability.

One of the most significant benefits of an inventory program is the ability to save time and money. By automating inventory management tasks, businesses can eliminate manual processes, reducing the risk of errors and the need for additional staff.

Reduced Labor Costs

- Automated inventory tracking eliminates the need for manual counting and data entry, reducing labor costs.

- Real-time inventory visibility enables businesses to identify and address stock discrepancies quickly, minimizing the need for additional staff to conduct physical inventory counts.

Best Practices for Inventory Management

Effective inventory management is crucial for small businesses to maintain optimal stock levels, reduce waste, and improve profitability. Here are some best practices to consider:

Implementing a robust inventory tracking system is essential to monitor stock levels in real-time. This allows businesses to identify items that are running low or overstocked, enabling timely replenishment or clearance.

Forecasting Demand

Accurate demand forecasting is vital for anticipating future sales and adjusting inventory levels accordingly. Businesses can utilize historical sales data, industry trends, and customer feedback to develop reliable forecasts. This helps avoid stockouts or excess inventory, ensuring optimal stock levels to meet customer demand.

Optimizing Inventory

Inventory optimization involves finding the balance between holding sufficient stock to meet customer needs while minimizing carrying costs. Businesses can employ techniques like ABC analysis, which categorizes inventory items based on their value and demand, and just-in-time (JIT) inventory management, which aims to minimize inventory holding time and reduce waste.

Regular Inventory Audits

Regular physical inventory audits help ensure accuracy and identify discrepancies between actual stock levels and records. This allows businesses to rectify errors, prevent shrinkage, and maintain reliable inventory data.

Effective Supplier Management

Establishing strong relationships with suppliers is crucial for timely delivery and product availability. Businesses should evaluate suppliers based on factors such as reliability, lead times, and pricing, and maintain open communication to ensure smooth inventory replenishment.

Utilizing Technology

Inventory management software can streamline processes, automate tasks, and provide valuable insights. These tools offer features such as real-time inventory tracking, forecasting, and reporting, enabling businesses to make informed decisions and improve inventory efficiency.

Training and Education

Training staff on proper inventory management practices is essential to ensure accuracy and consistency. Businesses should provide clear guidelines, establish roles and responsibilities, and offer ongoing training to keep employees up-to-date on best practices.

Trends in Inventory Management

The landscape of inventory management is constantly evolving, driven by technological advancements and changing business practices. These trends are significantly impacting small businesses, shaping their strategies and operations.

One notable trend is the rise of cloud-based inventory management systems. These systems offer real-time visibility into inventory levels, streamline ordering processes, and provide valuable analytics. Small businesses are increasingly adopting these solutions to improve efficiency and reduce costs.

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are revolutionizing inventory management by automating tasks, predicting demand, and optimizing stock levels. AI-powered systems can analyze historical data, identify patterns, and make informed decisions, reducing the risk of overstocking or understocking.

Radio Frequency Identification (RFID) and Internet of Things (IoT)

RFID and IoT technologies enable real-time tracking of inventory items, providing businesses with unprecedented visibility and control. RFID tags attached to products can be scanned to provide accurate inventory counts, while IoT devices can monitor environmental conditions, such as temperature and humidity, to ensure optimal storage conditions.

Just-in-Time (JIT) Inventory Management

JIT inventory management aims to minimize inventory levels by receiving products only when they are needed. This approach reduces storage costs, frees up cash flow, and improves efficiency. Small businesses are embracing JIT principles to streamline their supply chains and respond quickly to changing market demands.

Future of Inventory Management

The future of inventory management is bright, with technology expected to play a major role in shaping the industry.

Technology’s Impact, Inventory programs for small businesses

Technology will continue to have a significant impact on inventory management, with new technologies emerging that will help businesses to manage their inventory more efficiently and effectively. These technologies include:

- Artificial intelligence (AI):AI can be used to automate many of the tasks associated with inventory management, such as forecasting demand, optimizing inventory levels, and generating reports.

- Machine learning (ML):ML can be used to analyze data and identify patterns, which can help businesses to make better decisions about their inventory.

- Blockchain:Blockchain is a distributed ledger technology that can be used to track the movement of inventory throughout the supply chain.

Conclusion

In conclusion, inventory programs are indispensable tools for small businesses looking to optimize their inventory management practices. By leveraging these powerful solutions, businesses can gain greater visibility into their stock levels, reduce waste, improve customer satisfaction, and ultimately drive profitability.

As technology continues to advance, inventory programs will become even more sophisticated, offering even greater benefits to small businesses in the years to come.

Common Queries

What are the key benefits of using an inventory program for small businesses?

Inventory programs offer numerous benefits for small businesses, including improved inventory accuracy, reduced stockouts, increased sales, optimized cash flow, and enhanced customer satisfaction.

How do I choose the right inventory program for my small business?

When selecting an inventory program, consider factors such as your business size, industry, budget, and specific inventory management needs. Look for a program that offers the features and functionality you require, is easy to use, and provides reliable support.

Can inventory programs help me save money?

Yes, inventory programs can help small businesses save money by reducing waste, optimizing stock levels, and improving efficiency. By accurately tracking inventory levels, businesses can avoid overstocking and minimize losses due to spoilage or obsolescence.