Inventory tracking system for small business – Inventory tracking systems for small businesses have emerged as a game-changer, offering a lifeline to streamline operations, optimize stock levels, and unlock a world of benefits. Dive into this comprehensive guide to discover how these systems can revolutionize your inventory management, empowering you to make informed decisions and drive your business towards greater heights.

Introduction to Inventory Tracking Systems for Small Businesses

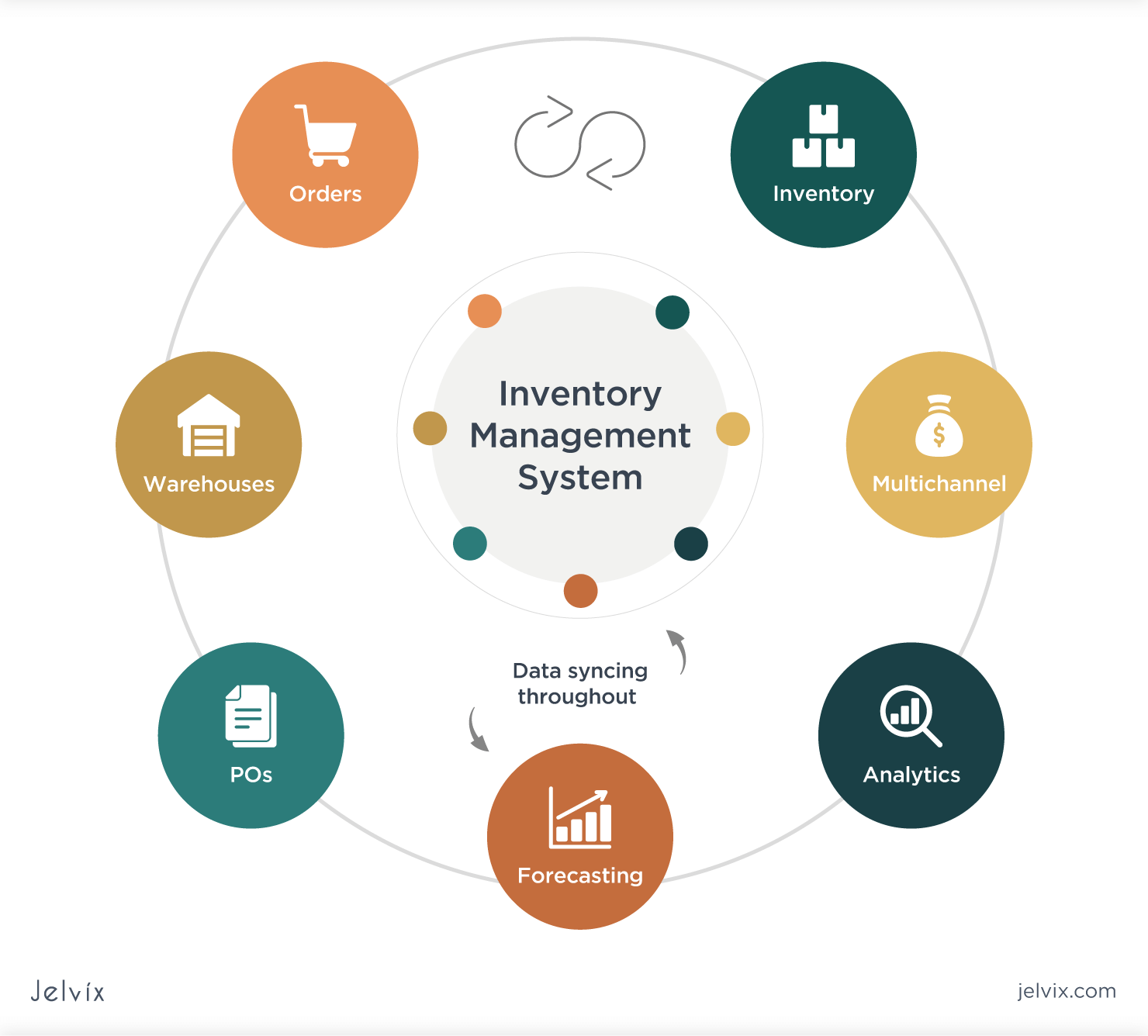

Inventory tracking systems are essential tools for small businesses to manage their stock levels effectively. These systems provide real-time visibility into inventory levels, allowing businesses to optimize their ordering, reduce waste, and improve customer satisfaction.

Without a proper inventory tracking system, small businesses face challenges in managing their stock, including:

- Inaccurate inventory counts

- Overstocking or understocking

- Lost or misplaced inventory

li>Inefficient ordering

Inventory tracking systems can streamline operations for small businesses in several ways:

- Automated inventory tracking

- Real-time inventory visibility

- Improved order accuracy

- Reduced waste

- Enhanced customer satisfaction

Types of Inventory Tracking Systems

Choosing the right inventory tracking system is crucial for efficient inventory management. Various systems are available, each with unique features, costs, and complexity levels. Understanding the different types and their pros and cons helps businesses select the system that best aligns with their needs.

Cloud-Based vs. On-Premises Systems

Cloud-based systems are hosted on remote servers, accessible through an internet connection. On-premises systems are installed and run on the business’s own servers or computers.

Cloud-based systems offer benefits like scalability, accessibility from anywhere, and reduced maintenance costs. On-premises systems provide greater control over data security and customization.

Choosing the Right System

Selecting an inventory tracking system requires careful consideration of business needs. Factors to consider include the size of the business, product range, inventory turnover rate, and budget.

Matching the system’s capabilities to business requirements ensures efficient inventory management, reduces costs, and improves overall business operations.

Key Features of an Effective Inventory Tracking System

An effective inventory tracking system is the cornerstone of efficient inventory management. It provides real-time visibility into inventory levels, enabling businesses to make informed decisions, minimize losses, and enhance customer satisfaction. Here are the essential features that every effective inventory tracking system should possess:

1. Real-Time Inventory Updates

Real-time inventory updates ensure that businesses have the most accurate and up-to-date information on their inventory levels. This is achieved through automatic data entry, such as barcode scanning or RFID tags, which eliminate the need for manual updates and reduce the risk of errors.

2. Multi-Location Tracking

For businesses with multiple locations or warehouses, a multi-location tracking system is crucial. It allows businesses to track inventory levels across all locations, providing a comprehensive view of their inventory and enabling them to optimize stock allocation and avoid overstocking or understocking at any location.

3. Low Stock Alerts

Low stock alerts are essential for preventing stockouts and ensuring that businesses can meet customer demand. These alerts notify businesses when inventory levels fall below a predefined threshold, allowing them to take timely action, such as placing replenishment orders or adjusting production schedules.

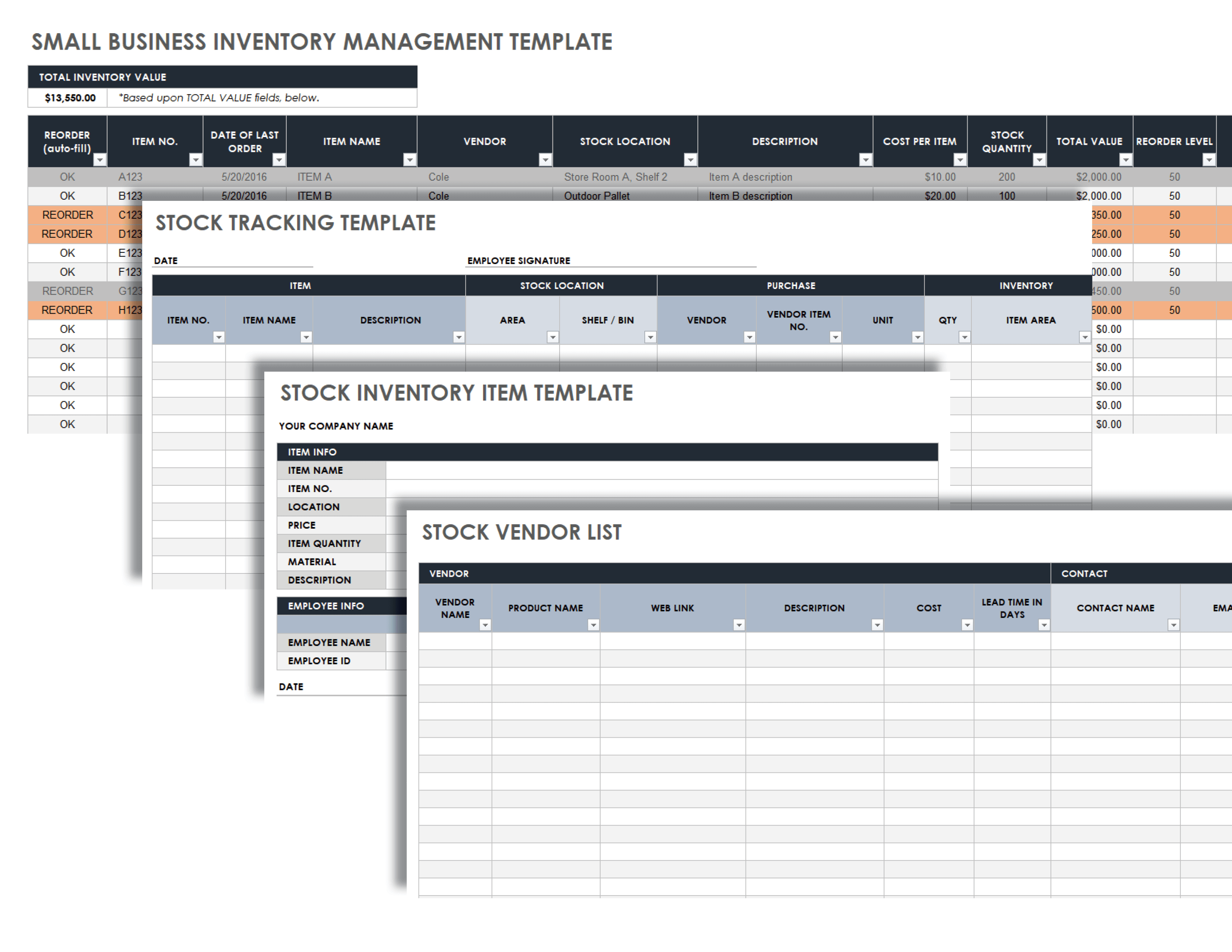

4. Customizable Reports

Customizable reports provide businesses with the flexibility to generate reports tailored to their specific needs. These reports can include data on inventory levels, stock movements, and sales trends, enabling businesses to analyze their inventory performance and make informed decisions.

5. Integration with Other Systems

Integration with other systems, such as accounting or e-commerce platforms, streamlines inventory management and eliminates the need for manual data entry. This integration ensures that inventory data is consistent across all systems, reducing the risk of errors and improving efficiency.

Implementation Considerations

![]()

Implementing an inventory tracking system requires careful planning and execution. The following steps are crucial for a successful implementation:

Planning:Define the scope and objectives of the system, gather requirements, and create a detailed implementation plan.

Data Migration:Transfer existing inventory data from the old system to the new one accurately and securely.

Training:Provide comprehensive training to users on the new system’s features and functionality.

Best Practices

To ensure a smooth implementation, consider the following best practices:

- Establish clear roles and responsibilities for the implementation team.

- Use a phased approach to minimize disruptions.

- Test the system thoroughly before deployment.

- Communicate regularly with stakeholders to keep them informed and engaged.

- Seek support from the vendor or a consultant if needed.

Benefits of Using an Inventory Tracking System

Implementing an inventory tracking system offers numerous benefits for small businesses, ranging from improved inventory accuracy to reduced waste and optimized stock levels.An effective inventory tracking system provides real-time visibility into stock levels, allowing businesses to accurately track the flow of goods in and out of their inventory.

This enhanced visibility helps businesses identify and address discrepancies, such as overstocking or understocking, leading to improved inventory accuracy.Moreover, an inventory tracking system automates inventory management tasks, reducing the risk of human error and the associated costs. By streamlining inventory processes, businesses can reduce waste and spoilage, as well as the need for manual counting and reconciliation.Furthermore, an inventory tracking system helps businesses optimize stock levels by providing insights into demand patterns and sales trends.

This information enables businesses to make informed decisions about inventory levels, ensuring they have the right amount of stock to meet customer demand without incurring excessive carrying costs.

Case Study: Small Business Success, Inventory tracking system for small business

ABC Company, a small hardware store, implemented an inventory tracking system and experienced a significant improvement in its inventory management. The system provided real-time visibility into stock levels, enabling the store to identify and address discrepancies promptly. As a result, ABC Company reduced inventory shrinkage by 15% and increased inventory turnover by 20%.

Last Word: Inventory Tracking System For Small Business

In the ever-evolving landscape of small business, inventory tracking systems stand as a beacon of efficiency and accuracy. By embracing these tools, businesses can unlock a wealth of benefits, transforming their inventory management practices and paving the way for sustained growth and success.

Helpful Answers

What are the key benefits of implementing an inventory tracking system for small businesses?

Inventory tracking systems empower small businesses with enhanced inventory accuracy, reduced waste, optimized stock levels, improved customer satisfaction, and streamlined operations, leading to increased profitability and efficiency.

How can small businesses choose the right inventory tracking system?

Selecting the optimal inventory tracking system involves carefully evaluating business needs, considering factors such as the number of SKUs, transaction volume, budget, and desired features. Cloud-based systems offer flexibility and scalability, while on-premises systems provide greater control and security.

What are the common challenges faced by small businesses in inventory management?

Small businesses often grapple with challenges such as manual processes, lack of real-time visibility, overstocking or understocking, and difficulty in tracking product movement. Inventory tracking systems effectively address these challenges, providing a centralized and automated solution.